Code: NCS_POL_01

Folded shelf for NC holders NCS POL 0140.75 Eur without VAT

(49.31 Eur with VAT)

Folded shelf for NCS cabinets to store plastic beds for NC tools.

Code: 2005 D10

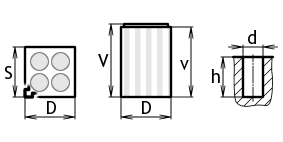

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 10 mm in diameter. You can full description and parameters

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 10 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: NCS_POL_01

Folded shelf for NC holders NCS POL 0140.75 Eur without VAT

(49.31 Eur with VAT)

Folded shelf for NCS cabinets to store plastic beds for NC tools.

Code: NCS_POL_02

Folded shelf for NC holders NCS POL 0234.29 Eur without VAT

(41.49 Eur with VAT)

Folded shelf for NCS cabinets to store plastic beds for NC tools.

Code: NCV_KAS_01

Plastic bed carrier NCV KAS 0131.42 Eur without VAT

(38.02 Eur with VAT)

Removable plastic bed carrier 100 x 100 mm, load capacity 40 kg.

Code: NCV_KAS_02

Plastic bed carrier NCV KAS 0231.42 Eur without VAT

(38.02 Eur with VAT)

Removable plastic bed carrier 80 x 80 mm, load capacity 40 kg.

Code: 2000 D3

Plastic CNC bed for milling cutters with a cylindrical shank of 3 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing miniature cutters with a cylindrical shank with a diameter of 3 mm, grinding bodies and other small tools. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2001 D4

CNC plastic bed for milling cutters with a cylindrical shank of 4 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing miniature cutters with a cylindrical shank of 4 mm in diameter, grinding bodies and other small tools. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2002 D5

Plastic CNC bed for milling cutters with a cylindrical shank of 5 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing small or miniature cutters with a cylindrical shank of 5 mm in diameter, grinding bodies and other small tools. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2003 D6

Plastic CNC bed for milling cutters with a cylindrical shank of 6 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 6 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2004 D8

Plastic CNC bed for milling cutters with a cylindrical shank of 8 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 8 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2006 D12

CNC plastic bed for milling cutters with a cylindrical shank of 12 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 12 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2007 D14

CNC plastic bed for milling cutters with a 14 mm cylindrical shank2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 14 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2008 D16

CNC plastic bed for milling cutters with a cylindrical shank of 16 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 16 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2009 D18

CNC plastic bed for milling cutters with a cylindrical shank of 18 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank with a diameter of 18 mm. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2010 D20

CNC plastic bed for milling cutters with a 20 mm cylindrical shank2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 20 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2011 D25

Plastic CNC bed for milling cutters with a cylindrical shank of 25 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters, drills, reamers and other tools with a cylindrical shank of 25 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2012 D30

Plastic CNC bed for milling cutters with a cylindrical shank of 30 mm2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing cutters and other tools with a cylindrical shank of 30 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2036 D2.35

CNC plastic bed for 2.35 mm cylindrical shank cutters2.59 Eur without VAT

(3.13 Eur with VAT)

The box is intended for storing miniature cutters with a cylindrical shank with a diameter of 2.35 mm, grinding bodies and other small tools. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2057 D32

Plastic CNC bed for milling cutters with a cylindrical shank of 32 mm2.91 Eur without VAT

(3.52 Eur with VAT)

The box is intended for storing cutters and other tools with a cylindrical shank of 32 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

Code: 2058 D40

Plastic CNC bed for milling cutters with a cylindrical shank of 40 mm2.91 Eur without VAT

(3.52 Eur with VAT)

The box is intended for storing cutters and other tools with a cylindrical shank of 40 mm in diameter. You can create any combination of individual elements. The elements are connected using a dovetail joint. Choice of red RAL 3020 or blue RAL 5015.

The building block system of boxes is used for the orderly and clear storage of tools at workplaces and in warehouses.

The boxes are made of ABS material in two colors, red (RAL 3020) and blue (RAL 5015). You can find a detailed description of individual parts in the online catalog.

The boxes are designed as a highly variable workshop kit. They are connected using a dovetail groove in any assembly. A fuse is used to prevent the assembly from being disassembled. If you need to disassemble the assembly again, the fuse must first be released for the individual parts.

All parts of the kit can be combined not only with each other, but also with boxes, panels and expansion elements.

When creating reports, follow the instructions. It is especially important to maintain the correct orientation of the kit parts during assembly. Incorrect orientation will make other parts impossible to connect.

You can download the instructions here!

Among the components of the kit you will find special boxes for drill sets and boxes for storing IMBUS keys or an electrode holder.

In the boxes for drills, the diameters of the storage cavities are graduated in 0.1mm increments and have labels. The description speeds up the finding of the necessary drill, and the grading helps to correctly place the drill back in its proper place.

There are two simple rules to follow when creating reports. This will prevent difficulties and avoid a bad experience.

Users without previous experience are advised to take stock of the overall arrangement of the assembly on squared paper before starting work. This can be especially useful when combining parts with different join modules.

On each box you will find four different corners. Only one of them has an arrow shape and is called a positioning corner.

First rotate each element of the system correctly before connecting it to the assembly. The positioning corner should point to the lower (or closer) left corner of the resulting assembly (see Fig. 2).

When creating an assembly, always first connect the individual boxes to the whole in the crosswise direction from left to right (direction 1). If the row is wide enough, you can connect other parts in the longitudinal direction from front to back (or bottom to top, direction 2).

Following the correct connection order means that you start at the near left (or lower left) corner of the assembly and end at the far right (upper right) corner of the assembly.

jak-na-boxy-cz.pdf (1.11 MB) - Instructions for connecting boxes for printing